A promising eco-friendly candidate for bone tissue engineering

Scientists have developed the application of maleic acid-treated bacterial cellulose (MA-BC) enhancing the innovation of bone repair.

A recent research collaboration, between scientists in Nanjing, China and the USA, has been able to successfully prepare a controllable bacterial cellulose (BC)-based bio-ink for 3D printing. The scientists modified neat BC with maleic acid (MA) treatment. A MA-BC-based bio-ink application in bioprinting may promote tissue repair using an eco-friendly candidate that has mild reaction conditions.

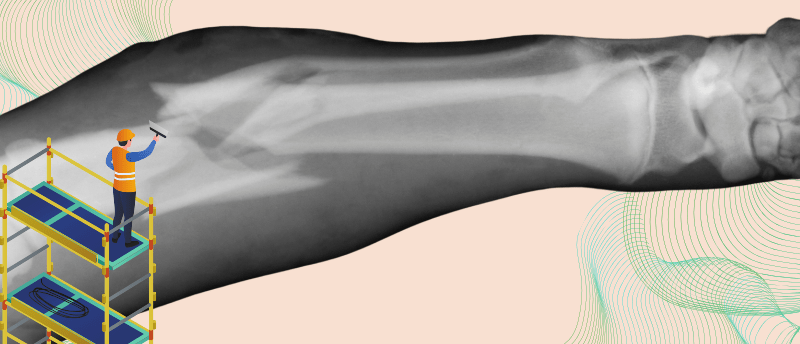

Scaffold fabrication is an essential step in the production of functional tissue constructs, cutting-edge materials at the forefront of tissue engineering. Constructing artificial ‘scaffolds’ with biologic functionalities is a promising avenue in bone tissue engineering; aiming to address bone injuries and defects. The FDA has approved artificial skin and cartilage but applications in human patients are currently limited.

BC is an exopolysaccharide produced through bacterial fermentation, which has been established as a useful material for scaffold fabrication. BC has a suite of unique and useful properties such as ‘extensibility, compressive strength, relaxation ability, viscoelasticity and poroelasticity’. Due to these unique properties, BC has expanded its functionality in various fields. However, due to the dense and intertwined nature of BC fibers, there are limitations that prohibit use for certain applications such as 3D printing scaffolds for bone regeneration.

Taking a bioengineering approach to ear reconstruction

Taking a bioengineering approach to ear reconstruction

Researchers have combined 3D printing and tissue engineering techniques to create a replica of an adult human ear that resembles its shape, size and biomechanical properties.

To address this limitation the team set out to find a way to make BC more malleable and amenable to 3D printing techniques. Previous work has highlighted MA as an ecofriendly and efficient chemical that has been successful in the treatment of cellulose materials. When introduced, the carboxylic groups in MA esterify with the hydroxyl groups in cellulose and disperse the microfilaments in BC matrix. This MA-mediated modification has the potential to yield homogenous short cellulose dispersions, exhibiting improved physiochemical properties for 3D printing and enhanced osteogenic bioactivities imperative for the development of bones.

With these facts in mind, the researchers investigated the optimal ratio of MA to BC that would yield an optimized material for the 3D printing of scaffolds for bone regeneration applications.

The team was successful in producing a MA-BC-Gelatin (GEL) gel by adjusting the volumes of MA solutions, achieving good printable performance and promoting bone repair ability. An initial 60% w/V solution of MA with a solid-liquid ratio from 1:50 (w/V) was used to achieve homogeneous BC dispersions whilst preserving its crystalline and chemical properties.

The results gathered indicated that the BC/MA solution with a ratio of 1:30 demonstrated the best pre-treatment performance to obtain MA-BC. The formulated MA-BC-GEL gels possessed excellent biocompatibility, a significant ability to express the alkaline phosphatase gene and osteogenic-related genes and facilitated the formation of mineralized nodules. These favorable properties which demonstrated promising suitability as a bio-ink for 3D bioprinting applications.

The scientists expect this study to provide valuable insights into the potential application of MA-BC dispersions in bone tissue engineering, facilitating the proliferation and differentiation of osteocytes.