Choosing the right stem cell media: an interview with Biological Industries USA’s Dan Haus

Dan Haus, Application Development Scientist at Biological Industries USA, discusses why choosing your media is still the most important factor in stem cell cultures.

In this interview, Dan Haus, Application Development Scientist at Biological Industries USA, explains why induced pluripotent stem cells (iPSCs) require more attention than traditional cell types and discusses why choosing your media is still the most important factor in stem cell cultures.

Dan Haus

After graduating from the University of California, Irvine (CA, USA) in 2015 with a PhD in Biomedical Sciences, Daniel joined BI-USA as an Application Scientist specializing in product support for cell culture and stem cell research as well as developing application-specific collaborations. Daniel’s research background includes working to understand protein function in Huntington’s disease, developing methods for the derivation of xeno-free human neural stem cells from pluripotent stem cells and evaluating the potential for transplanted human neural stem cells to improve cognition in animal models of traumatic brain injury.

Can you introduce Biological Industries?

Biological Industries, or BI, as we’ve come to be known by our customers, has been manufacturing various types of cell culture media for over 35 years. Headquartered in Israel, BI started out making plant culture media, but quickly became sought after and contracted to produce high quality media for research groups for a variety of cell types and applications. From all this experience producing, developing and optimizing formulations over the years, BI has truly become cell culture media experts.

Specifically, we have developed a focus on stem cell culture systems, where we have put much of our research and development (R&D) efforts into developing tools and supporting researchers in this field to help drive this incredible technology toward cures and applications in the clinic. Our strength is not only with the experience of our people and our networks, but also the know how we have with good manufacturing process (GMP) manufacturing and regulatory requirements.

Biological Industries USA (BI-USA), is a newer division of BI located in the United States, which was established to help focus on the stem cell research market in North America as well as contributing to global education and training initiatives in regenerative medicine.

How long have you been doing stem cell research and how has the research evolved since you first started working in the lab?

I’ve been involved in cell culture for over 10 years and began studying and working with human embryonic stem cells (hESCs) in earnest about 8 years ago. The first hESCs I worked with were cultured on mouse fibroblast feeder cells and cultured in media that we made ourselves in the lab. At that time, our lab was evaluating hESCs and their neural derivatives for use as therapeutics and we were a beta-test site for some of the first commercially available xeno-free media and substrates.

Since working with those first reagents, we have found that many of the xeno-free products that are available today work just as well, if not better, then the standard lab-made versions. Over time, I’ve seen how these types of collaborations between academic labs and industry has helped drive and refine the advancement of the everyday tools we use in the lab and has made the work involved in stem cell culture much less tedious and more accessible to everybody.

How do the requirements for iPSC culture differ to non-stem cell culture?

At the most basic level, nearly all cell types need two things for in vitro cell culture: a substrate to grow on and nutrients to consume. How the various cell types differ in these requirements is largely related to the degree of specificity of their needs. For example, some classic immortalized cell lines, like HeLa cells, grow in culture well using only a fairly basic medium containing vitamins, minerals and serum.

Many stem cells, on the other hand, are much more specific in their needs and require a finely tuned medium and substrate combination that effectively mimics their in vivo niche. In general, stem cells require much more effort to identify the specific nutrients, attachment proteins, growth factors and cytokines that best support their growth in culture. In addition, many stem cell subtypes require careful daily monitoring to keep them healthy and proliferating.

What are some common cell cultures challenges that iPSC scientists face?

By using many of the commercially available cell culture products, like the media, substrates, proteins and cytokines, many of the technical difficulties we saw in the past are now dramatically reduced. Cell culture products are now highly optimized and defined, which makes them very consistent every time you use them and practically eliminates the variability that is often seen in “homebrew” media.

Now, instead of the challenge of variable lab-made media, I see some of the challenges shifting to identifying and understanding the variability across cell lines themselves. The use of consistent, defined media across the board has helped make these subtle variations detectable. Culture conditions can now be further optimized to address the unique needs and responses of specific iPSC lines, for example.

What are some of the advantages of using a defined medium over lab-made cell culture media?

The biggest pitfall with “homebrew” cell culture media is its variability. In the lab, variability is introduced every time the media is made due to variations in both the raw ingredients themselves and the individual person preparing the media. When making media in the lab, it’s best to have one person or team trained and dedicated to media preparation, ensuring that they mix and measure each and every batch the same way each time. Media production done on a rotating schedule may free up some time for scientists to focus on other things, but it often has the unfortunate consequence of generating media that is never prepared in exactly the same manner, ultimately producing results that can vary widely due to differences in media preparation.

On the other hand, when using a defined, commercially produced medium, the lab is saving time and effort upfront by not requiring anyone in the lab to make it at all. Nearly all of the human error of media preparation is removed by the control systems and quality assurance/quality control criteria set by the manufacturer, providing much higher consistency in the final product from batch to batch. Nothing is ever forgotten or added twice by accident and all the mixing, filtering and aliquotting is automated. The result is a media with little-to-no variability that improves reproducibility and efficiency of experiments across the board.

What features of GMP are particularly relevant to iPSC culture?

There are many features of GMP that are important for iPSC labs to consider, especially if the results of the iPSC work is intended to generate therapeutic-grade cells or cell by-products for clinical applications. While culturing iPSC in a culture system that is xeno-free is not mandatory by the US FDA prior to human transplantation, it is a common belief that the path to FDA approval can be shortened by using defined, xeno-free and even animal-component free products during the pre-approval process for iPSC-based therapies.

Another often overlooked feature of GMP is that, at its core, GMP is about implementing systems to assure that processes are defined and followed accurately. In this way, following GMP guidelines for cell manufacturing generates stem cell lines and derivatives in a manner that is more consistent and reproducible — and ultimately more safe for the patient.

If someone is interested in using NutriStem® hPSC Medium, what are some tips for making the switch from a “homebrew” media or other commercially available media?

NutriStem hPSC Medium stands out among some other commercially available media in that it is a very defined and minimal formulation. For one thing, NutriStem hPSC Medium contains a very low, basal level of proteins and growth factors. If switching from a medium that contains very high levels of basic fibroblast growth factor (bFGF), for example, the cells may require a more gradual switch to the new medium, as some cell types can become overdependent on high levels of bFGF over time. The differences in formulations between media may also cause cells to take on a slightly different morphology than what you may be used to.

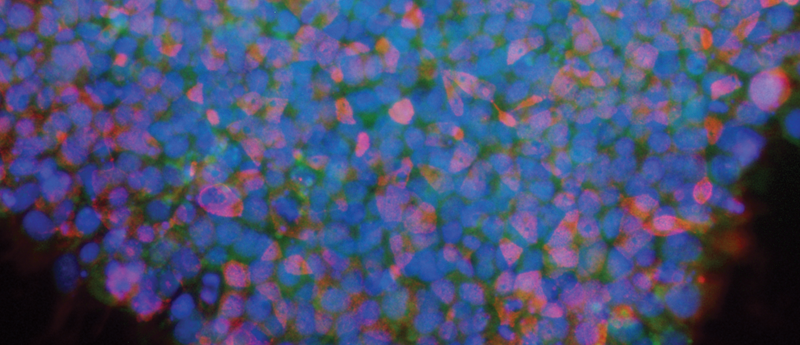

Until you are comfortable with the subtle differences in morphology and growth habits in the new media, it is a good idea to use a live-staining antibody to look at cell surface markers for pluripotency, such as SSEA-4 or TRA-1-60, to more accurately assess the health and condition of the cells. Evaluating a new media takes some dedication, so be sure to give the cells enough time in the new environment before coming to conclusions and always keep a well or two in the old medium as a backup and a control.

What type of cells and culture conditions is NutriStem® hPSC Medium compatible with?

Each batch of NutriStem hPSC Medium is internally validated on H1 and/or H9 hESCs and is used routinely across the world with hundreds of unique cell lines. NutriStem also supports the reprogramming of many different starting cell types and has successfully generated new iPSC lines from fibroblast, patient-specific and disease-specific target cells.

NutriStem hPSC Medium has been used successfully to culture pluripotent stem cells on a variety of substrates, including mouse and human fibroblast feeder layers, Matrigel®, Cultrex®, Synthemax®, multiple vitronectin proteins, laminin-511, laminin-521 and even biomimetic spider-silk. Lately, labs have started using NutriStem hPSC Medium to culture hPSCs as single cells, to derive clonal lines and to expand cells in 3D clusters within bioreactors.

What are some of the benefits of using NutriStem® hPSC Medium for culturing iPSCs?

NutriStem hPSC Medium is a defined, serum-free and xeno-free medium that is widely used for research and translational medicine applications. In addition to standard culture methods, NutriStem hPSC Medium has been shown by many labs to be highly flexible to a variety of different culture systems and applications. For instance, the combination of NutriStem hPSC Medium with Laminin-521 substrate has been shown to be the preferred media for expansion of iPSCs as single cells without the need for rho kinase (ROCK) inhibitors. NutriStem hPSC Medium is also the preferred media used in many reprogramming protocols, including reprogramming cells from peripheral blood using nonmodified mRNA.

For research in the area of regenerative medicine, NutriStem hPSC Medium is very amenable to downstream clinical use due to the definition and purity of its components, as well as the fact that it is produced under cGMP conditions in an ISO-certified facility. Moreover, NutriStem has a specific Drug Master File (DMF) accepted at the FDA, which can greatly accelerate the approval process for technologies heading for clinical trials.

How do you see stem cell culture evolving in the future?

Today, I feel like we are closer than ever to having clinically approved therapies based on pluripotent stem cells. However, one area that still needs to evolve is the standardization of protocols and reagents across the field. Knowing that the stem cells themselves inherently contribute some variability to each experiment, optimizing and standardizing protocols with defined reagents across the board will allow us to reliably reproduce results in different labs and at different timepoints. From this point of view, we should strive to optimize and standardize in multiple areas, including cell culture conditions, characterization, and differentiation techniques.

Acknowledgements & Declarations

- Dan Haus is employed by Biological Industries USA.