Tofu in a fibroblast marinade

In this article, Geoffrey Potjewyd (University of Manchester, UK) reviews a recent report from Journal of Materials Chemistry B.

Geoffrey Potjewyd1

1Regenerative Medicine & Neuroscience PhD student, University of Manchester (UK)

Tofu, also known as bean curd, has been praised as a healthy food source with low calorie and high protein and mineral contents. It has also been commonly used as a bland meat alternative which can be marinated to suit most people’s tastes.

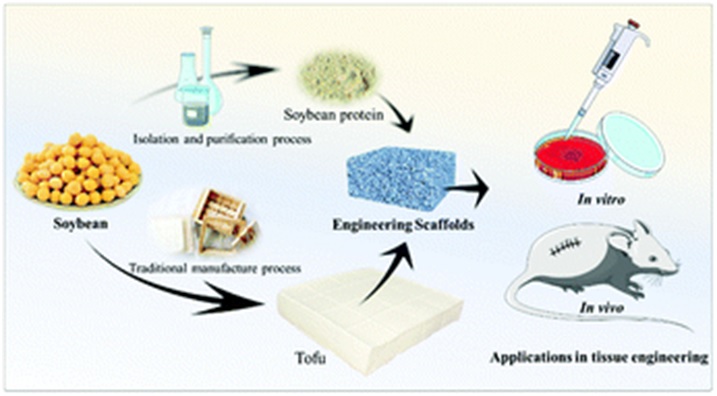

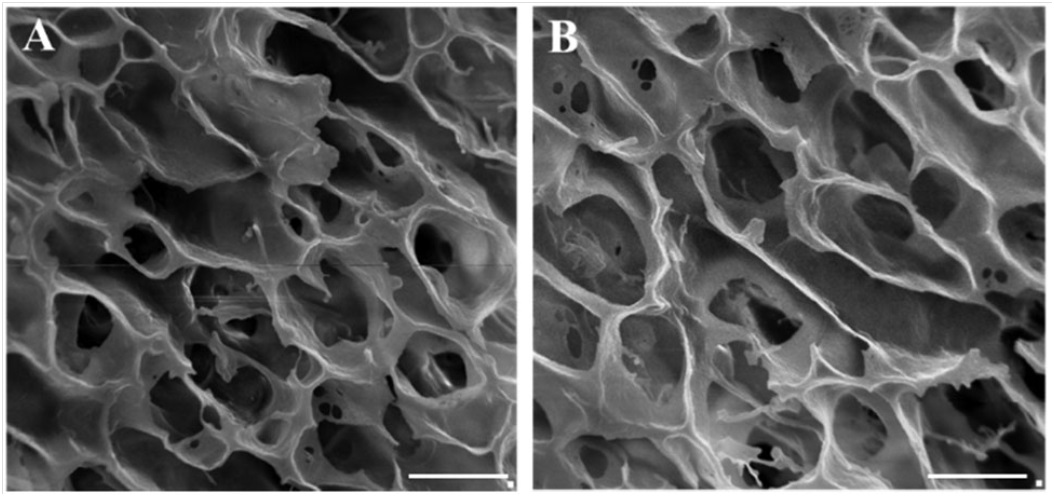

Now, the marinade for this vegetarian- and vegan-friendly food is being swapped from spices to cells, and has been touted as a potential scaffold for regenerative medicine and tissue engineering applications. This is owing to the aforementioned protein and mineral content, in addition to the porous microstructure of tofu that allows for both the seeding of cells into the block of food and the dispersal of oxygen and nutrients throughout the construct.

Researchers from a multi-institute collaboration have established that tofu can be used, and a very similar soybean-based scaffold can be used as a platform for growth of cells and even for transplantation into animal models.

They seeded fibroblast (3T3) cells into both soybean constructs and found that cells could attach, proliferate and maintain a high viability within the construct over 7 days. This data allowed the group to consider how the construct would fare when transplanted into an animal model.

Following implantation of the scaffolds into rats, the group observed a minimal inflammatory response. The group indicated that this showed biocompatibility, with low levels of fibrous capsules and fiber bundles, low cytotoxicity and scaffold integration with the surrounding tissue.

The group hypothesizes that the integration of scaffold to the surrounding tissue was instigated from the presence of the high protein content in soya bean proteins. The porosity of the tofu and soybean has the potential to allow for nutrient and oxygen flow throughout the tissue construct, initiating neovascularization in early stages of wound healing. The authors state that this could lead to tofu and soybean based-scaffolds being used for wound healing applications, promoting the wound healing response and increasing recovery following damage.

Although it may seem that every tissue engineer will be clamoring to bulk buy soybean and tofu, there are some limitations to using this protein. The physical stiffness of the tofu is in between that recorded for skeletal muscle and bone, and is much higher than soft tissues like the brain. This indicates that the suitability of this food material is limited to non-soft tissues, which is not a disadvantage if you are researching these stiffer tissues. Further research may be needed to evaluate the tuneability of soybean physical properties from the manufacturing process, with the group finding that there was no significant difference in the physical properties of the tofu and soybean-protein alternative scaffold.

Overall the authors state that this research paves the way for the evaluation of other food materials for use in tissue engineering studies. The positive results found from both in vitro and in vivo culture observed in this study may lead to a more widespread use of tofu-based scaffolds in regenerative medicine projects. In addition to the favorable physical and biochemical properties of tofu, it is also a relatively cheap option to other scaffold constructs.

Huang J, Huang K, You X, Liu G, Hollett G, Kang Y et al. Evaluation of tofu as a potential tissue engineering scaffold. J. Mater. Chem. B. 10.1039/C7TB02852K (2018) (ePub ahead of print)