Novel 3D printing method for sophisticated soft tissues

An inkjet printing method has unlocked the ability to print with slow-curing plastics. This expands the suite of materials available to 3D printing and facilitates the fabrication of delicate tissue types.

A research team composed of scientists from Eidgenössische Technische Hochschule Zürich (Switzerland) and Inkbit (MA, USA), a Massachusetts Institute of Technology (MA, USA) spin-off, has developed a 3D printing technology that enables the use of slow-curing polymers. This technology allows, not only for the use of slow-curing polymers, but also the simultaneous printing of different tissue types in one printing process to generate delicate and sophisticated structures.

3D printing produces structures through a layer-by-layer deposition process. The materials employed have been typically confined to fast-curing plastics, such as polyacrylates. Viscous forms are deposited and then subjected to a UV-curing process that immediately hardens the layers by cross-linking polymer chains. Processing of each layer typically occurs through a device that scrapes off surface irregularities.

Slow-curing polymers, like thiol-enes and epoxies, are incompatible with this method and so are excluded, despite their enhanced and tuneable elasticity, durability and robustness properties.

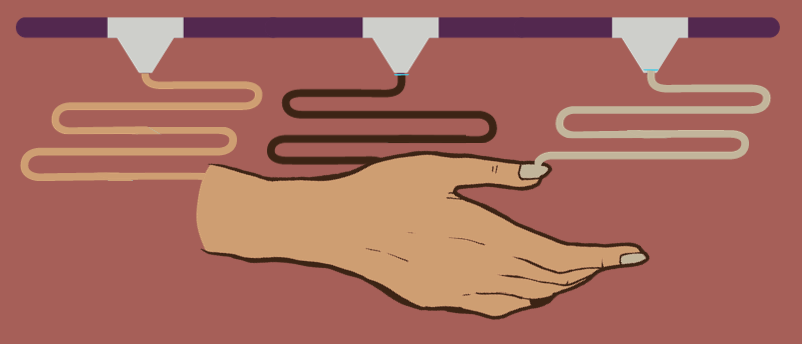

The research team at ETH Zürich has developed a technology called vision-controlled jetting, which utilizes a high-speed 3D vision system to generate depth maps of the printed surface. So, instead of scraping off surface irregularities, they are corrected by a compensatory printing feedback mechanism, which adjusts the flow rate of material to correct the irregularity and maintain an ideal planar surface.

The expanded suite of materials that can be used with this 3D printing method allows for the fabrication of more complex 3D printed tissues. The technology itself also facilitates the combination of soft, elastic and rigid materials to create delicate structures or parts with cavities if needed, all in one printing run.

The researchers demonstrated this by producing a heart-inspired functional fluid pump and a robotic hand complete with bones, ligaments and tendons. Both would not be feasible only with fast-curing polymers.

“We wouldn’t have been able to make this hand with the fast-curing polyacrylates we’ve been using in 3D printing so far,” explains Thomas Buchner, first author of the study. “We’re now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

You may also like:

3D printed neural stem cells offer hope for repairing brain injuries

3D printed neural stem cells offer hope for repairing brain injuries

The potential for customized treatments for brain injury follows research that showcases the ability to 3D print stem cells to replicate the cerebral cortex.

One step closer to biologically functional 3D printed tissues

One step closer to biologically functional 3D printed tissues

Researchers adapted volumetric bioprinting to create 3D biologically functional printed gels.