Optimizing exosome design to improve the delivery of gene therapies

Tony De Fougerolles is the CEO of Evox Therapeutics (Oxford, UK), a privately owned biotechnology company that develops novel exosome-based therapeutics for the treatment of rare and severe diseases with limited treatment options. At this year’s Advanced Therapies Europe (ATE; 5-7 September 2023; Estoril, Portugal) we caught up with Tony to discuss the challenges in advanced therapy delivery and how exosomes can be optimized for drug delivery.

Tony De Fougerolles is the CEO of Evox Therapeutics (Oxford, UK), a privately owned biotechnology company that develops novel exosome-based therapeutics for the treatment of rare and severe diseases with limited treatment options. At this year’s Advanced Therapies Europe (ATE; 5-7 September 2023; Estoril, Portugal) we caught up with Tony to discuss the challenges in advanced therapy delivery and how exosomes can be optimized for drug delivery.

What are some of the challenges that are currently associated with the delivery of gene therapies?

Broadly speaking, a lot of progress has been made in the development of gene therapies, whether they be gene-editing complex-, RNAi- or mRNA-based. However, these drugs need to be delivered into specific tissues and cells to be effective, and currently, their use is being hindered by an inability to deliver them to target sites.

While there are some successful delivery mechanisms, for instance for liver-directed RNAi and gene editing complexes and mRNA-based vaccine delivery, these are restricted to a few tissue types, when the current suite of therapeutics could be amenable to a dozen tissues. And so that’s what we at Evox and the field, in general, are trying to solve: enhancing tissue-specific therapeutic delivery, in particular to extrahepatic targets.

What are exosomes and how can they be engineered into drug-delivery vehicles?

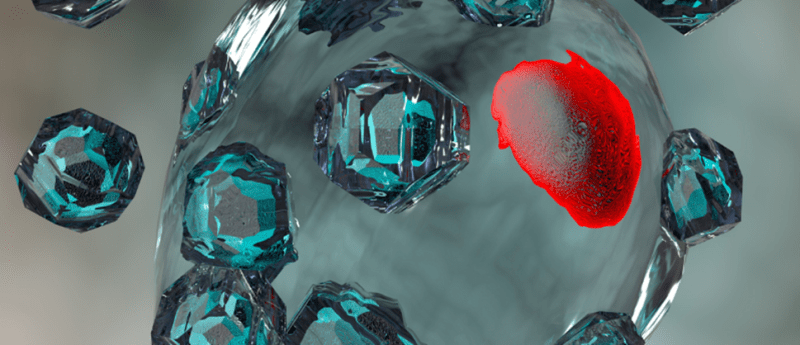

Exosomes are a really interesting type of modality. They’re small nanoparticles produced by every cell in the body. An average cell will make 5,000 to 10,000 exosomes per day, which contain proteins and RNA typical of that cell. However, what the cell puts into an exosome and secretes is not a mirror copy of a cell’s contents. Rather, the cells are specifically selecting what to put into an exosome and potentially using that to communicate with other cells.

At Evox, we have manipulated cellular control of exosome contents to introduce drugs into the exosomes that the cell is producing. Using a plasmid or a construct, we transfect a cell that has been engineered to produce our drug of choice with instructions, called sorting domains, which direct a cell to put that drug into the exosomes it’s naturally making. And so, ultimately, the cell makes the drug, loads it into its exosome and secretes it, and then we purify the drug-loaded exosomes secreted into the cell culture.

How are exosomes optimized for therapeutic delivery?

So, in terms of how we can engineer the exosomes, they can be modified by altering the instructions delivered by the sorting domains based on the therapeutic in question. The sorting domains can optimize drug delivery by instructing exosomes to present the drug on the surface if we want it to be displayed, retain it within the exosome to protect it, or to introduce cleavable elements. So multiple elements of the design can help us preferentially direct a drug-loaded exosome to the right tissue.

We can also engineer aspects of the exosome to improve cargo delivery to recipient cells using different fusogen proteins, expressed on the surface of the exosomes, improving their ability to safely deliver drugs inside the cell cytoplasm by a hundredfold or more.

What were some of the key takeaways from your presentation at ATE?

As I listen to folks here, the key takeaways in the field appear really to revolve around scaling manufacturing, but also having the analytic tools to analyze your product. And that’s something we found in the exosome space. It’s not just scaling exosomes, which we’ve been able to do, but as you understand the development analytics, you have a better understanding of your product, which allows you to make process improvements. I think that holds true not just for exosomes but for most of these advanced therapies.

If there was one wish that I could grant, to help optimize and facilitate the delivery of your exosomes and their target drug to a tissue, what would it be?

I think we have a pretty complete toolbox. I would probably say something along the lines of more CDMOs in the exosome space. So at the moment, we do all of our manufacturing in-house up to 200 liters. You know, there are a couple of players in that space, from a CRO or CDMO perspective. And I think, hopefully in a few years, the field will be sufficiently advanced that there will be a lot more CDMO options as it relates to larger-scale exosome manufacturing.