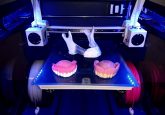

Vascularized heart 3D printed utilizing patient’s own cells and biological materials

Scientists at Tel Aviv University (Israel) have been the first to 3D print a vascularized, engineered heart from a patient’s own cells, which matches the immunological, cellular, biochemical and anatomical properties of the patient.

Banner image: ‘A 3D printed, small-scaled human heart engineered from the patient’s own materials and cells.’ Credit: Advanced Science. © 2019 The Authors [see below].

Scientists at Tel Aviv University (Israel) have been the first to 3D print a vascularized, engineered heart from a patient’s own cells. The printed heart reportedly matches the patient’s immunological, cellular, biochemical and anatomical properties.

“This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles and chambers,” explained study leader, Tal Dvir (Tel Aviv University).

With heart disease currently holding the position as the top cause of death among men and women in the United States, investigations into alternative options for the regeneration of the diseased heart are urgent. Heart donors are in short supply and transplantation is currently the only option for patients with end-stage heart failure.

“This heart is made from human cells and patient-specific biological materials. In our process these materials serve as the bioinks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models,” Dvir continued. “People have managed to 3D print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future.”

“At this stage, our 3D heart is small, the size of a rabbit’s heart,” added Dvir. “But larger human hearts require the same technology.”

Research published in Advanced Science describes how the team started with a biopsy of fatty tissue from the patient, which was separated intro cellular and a-cellular materials. As some cells were ‘reprogrammed’ to become pluripotent stem cells, the extracellular matrix was developed to become a personalized hydrogel.

The stem cells differentiated into cardiac or epithelial cells when mixed with the hydrogel, creating patient-specific, immune-compatible cardiac patches with blood vessels, which later became an entire heart.

“The biocompatibility of engineered materials is crucial to eliminating the risk of implant rejection, which jeopardizes the success of such treatments,” Dvir commented. “Ideally, the biomaterial should possess the same biochemical, mechanical and topographical properties of the patient’s own tissues. Here, we can report a simple approach to 3D-printed thick, vascularized and perfusable cardiac tissues that completely match the immunological, cellular, biochemical and anatomical properties of the patient.”

What’s next?

The team are reportedly working on culturing the printed hearts and teaching them to behave like hearts, before working on transplanting the 3D printed heart into animal models.

“We need to develop the printed heart further,” Dvir concludes. “The cells need to form a pumping ability; they can currently contract, but we need them to work together. Our hope is that we will succeed and prove our method’s efficacy and usefulness.

“Maybe, in 10 years, there will be organ printers in the finest hospitals around the world, and these procedures will be conducted routinely.”

Sources: Noor N, Shapira A, Edri R, Gal I, Wertheim L, Dvir T. 3D printing of personalized thick and perfusable cardiac patches and hearts. Adv. Sci. doi: 10.1002/advs.201900344 (Epub ahead of print) (2019); www.aftau.org/weblog-medicine–health?&storyid4704=2446&ncs4704=3