Closed, automated platform enables end-to-end manufacturing of hPSCs

Scientists from Cell and Gene Therapy Research and Development, Lonza Inc. (MD, USA), have developed a closed, automated and scalable platform which could enable larger scale manufacture of clinical-grade human pluripotent stem cells (hPSCs).

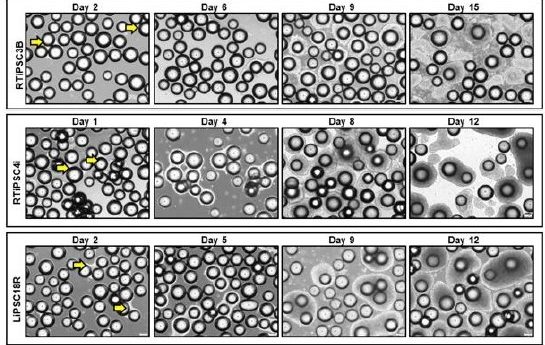

Large scale manufacture of clinical-grade cells for therapeutic purposes remains a challenge to developers. Any potential process requires large numbers of cells produced in a carefully controlled microenvironment. Producing the cell densities required using traditional 2D culture methods would be a costly endeavor. 3D cell culture methods are more robust and scalable but can require sequential passaging and supplemented small molecules for high-fold expansion.

In an article published in the International Journal of Molecular Sciences, the team detailed the development of the platform, which expands hPSCs in a controlled bioreactor using perfused L7™ TFO2 hPSC xeno-free media followed by cell harvest and concentration under closed conditions.

This method proved scalable to 1 L or 3 L bioreactor vessels and was GMP-compliant, recovering 94% of viable cells – a significant improvement on 64% reported in previous studies. Following cryopreservation, the cells could be thawed into either a 2D tissue culture platform or a 3D bioreactor to be further expanded or differentiated into the desired type. A 3D cell train, allowing transfer of cells from one vessel to another, could enabling scalable expansion and therefore commercial-ready production.

Immunofluorescence and flow cytometry analyses confirmed expression of hPSC-associated markers and the collected cells were able to differentiate into cells of the three germ layers.

The authors suggest that this system could make possible a completely 3D, closed and automated process and therefore a process which is more time-, cost- and labor-effective.

Source: Pandey PR, Tomney A, Woon MT et al. End-to-End Platform for Human Pluripotent Stem Cell Manufacturing. Int J Mol Sci. 21(1): 89 (2020).