Novel modular 3D-printed microfluidic system for continuous stem cell harvesting and manufacturing

Researchers from the University of Technology Sydney (Sydney, Australia) in collaboration with Regeneus (Pymble, Australia) generate a 3D-printed modular microfluidic closed system that can be utilized in the cellular manufacturing of mesenchymal stem cells (MSCs).

Microfluidics, the precise handling of fluid within a network of channels, has demonstrated great potential to manipulate cells and has promising applications within the bioprocessing industry. Existing microfluidic systems lack modularity, are prone to error and can be costly. Recent advances in 3D printing technology have enabled microfluidic systems to develop and become more industrially applicable.

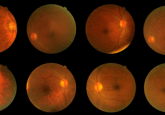

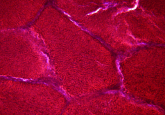

Recently, researchers from the University of Technology Sydney collaborated with industry professionals from the biotechnology company Regeneus to produce a 3D-printed modular microfluidic system containing two micromixers, one spiral microfluidic separator and one microfluidic concentrator. In their recently published research article, they discussed how this novel modular microfluidic system was then utilized to demonstrate the rapid detachment and separation of MSCs from microcarriers (MCs) while keeping the cells’ viability and functionality intact.

Typically, MC-based culture systems are advantageous as they can maximize cell manufacturing at a larger scale. Limitations of these existing systems involve the harvesting and detaching of the MSCs from MCs utilizing membrane-based filtration/centrifugation which can result in filter clogging or cell death. Moreover, methods such as centrifugation are time-consuming and can be cost-ineffective.

“Our cutting-edge technology, which uses 3D printing and microfluidics to integrate a number of production steps into one device can help make stem cell therapies more widely available to patients at a lower cost,” commented corresponding author Majid Ebrahimi Warkiani. “While this world-first system is currently at the prototype stage, we are working closely with biotechnology companies to commercialize the technology. Importantly, it is a closed system with no human intervention, which is necessary for current good manufacturing practices”.

This novel closed microfluidic system has the potential to overcome many limitations of currently existing cell therapy manufacturing systems and could be scaled up to process large volumes of MSCs and other cell types such as CAR-T cells. This system has the potential to advance large scale bioprocessing and manufacturing, making cellular therapies more cost-effective and accessible to those in need.