Uniform 3D-printed parts improved with nanocylinder vibrations

CREDIT: National Institute of Standards and Technology

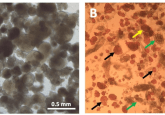

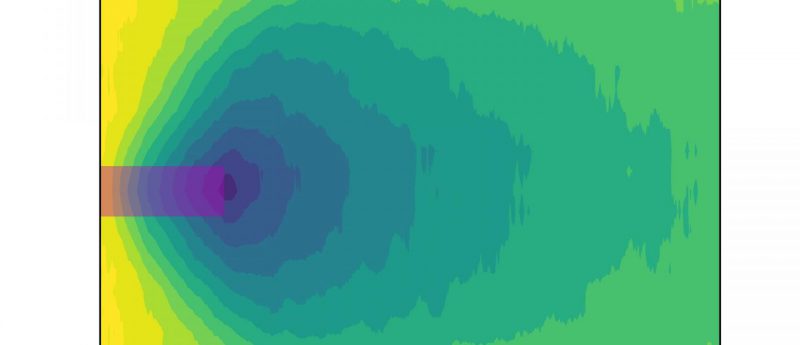

A team from the National Institute of Standards and Technology (NIST; MD, USA) has demonstrated a method of measuring the rate at which microscopic regions of a liquid raw material harden into a solid plastic when exposed to light, in an effort to improve the uniformity of 3D-printed parts. A custom atomic force microscope (AFM) at NIST with a nanometer-scale, cylinder-shaped tip, or 'nanocylinder', has enabled investigations into the complex process of curing resins, reacting under light to form polymers. The process includes controlling how much of the lights energy is utilized in forming the polymer, as well as how...