Technology digest: the importance of reagent consistency in culturing organoids

Organoids in drug and disease modelling

Traditional 2D cell culture has long been the mainstay of scientific research, enabling cells to be cultured reproducibly and inexpensively. However, 2D culture can never fully recapitulate the conditions within a biological system. Cells in vivo experience dynamic conditions from exposure to circulating molecules, such as cytokines and growth factors, and neighboring cells within the extracellular matrix (ECM). In order to achieve the best consistency culturing complex 3D structures, it is important to use high quality products. As reliance on animal models is reduced, these quality products used for 3D cultures will enable the discovery of the next generation of blockbuster treatments [1].

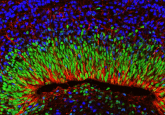

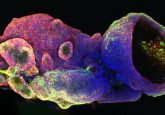

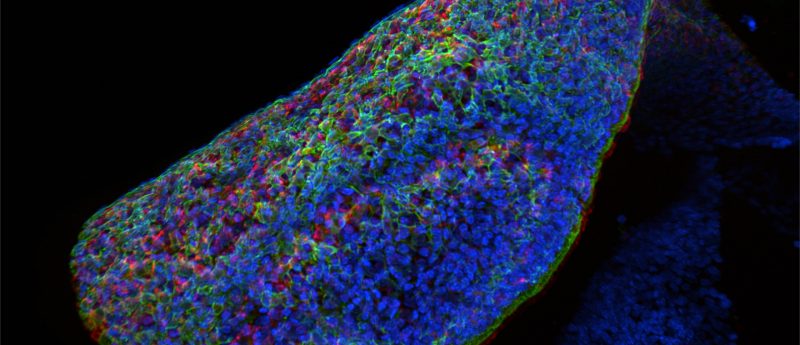

Organoids [2] therefore represent an important step forward in 3D cell culture. They are derived from progenitor cells, which, when provided with an environment that mimics their in vivo conditions, can be induced to differentiate into specific mini organs. Organoids can be triggered by certain cues and thereby mimic the response of the original tissue to injury or therapy [3]. However, the complexity of organoids mean that they are even more susceptible to variability in culture conditions.

Culture conditions and ensuring reagent consistency

Whatever cells you are culturing, consistency, from the starting product to your reagents and culture conditions, is crucial in producing consistent and high-quality results. A common method of organoid culture involves embedding progenitor cells on a liquid hydrogel [4]. The composition of the hydrogel is developed so that it closely resembles the in vivo ECM. Cultrex® UltiMatrix RGF BME is one such advanced matrix, an optimized mixture of structural proteins such as laminins, collagens and entactin that provides a physiological scaffold for organoid culture. Consistency in the ECM composition, and in the ratio of its components is a key factor for the growth and longevity of the cultured organoids.

Another important factor is the composition and definition of the growth medium [5]. The growth medium is often tailored to allow flexibility for the unique requirements of the specific organoid culture. According to Dr Talya Dayton, Hans Clevers’ Lab, Hubrecht Institute (The Netherlands), “one of the key features of our organoids in general….is the defined media that we use. This allows us to tailor the in vitro niche environment to the specific cells we are growing or to the cells that we are trying to generate in culture. This has been made possible, in part, through the use of a wide range of different growth factors and small molecules from R&D Systems and Tocris. We also used Cultrex for all [our] organoids.”

Ultimately, researchers can reap the benefit of bioproduction expertise and reduce user-dependent variation by using QC-validated, commercially available media. Yas Heidari, Product Manager for Protein & Cell Biology at Bio-Techne, explains “We routinely optimize our media formulations using design-of-experiments (DOE), and a diverse portfolio of recombinant proteins and small molecules. We also have a large bank of cells including primary cells for media testing and optimization. To keep our media and supplements as consistent and specific as possible, we have developed a host of in-house specialized assays to monitor growth, expansion, and differentiation for a variety of cell types”. Whether you are culturing cell lines or whole tissues and organoids, reducing biological variability will improve the culture consistency, making the system more valuable for its end application [6].

Organoid characteristics and minimizing variability

Robust organoid growth is dependent on presence and activity in the culture media of key growth factors such as R-Spondins, Noggin and Wnt-3a. To induce proper differentiation of progenitor cells the use of R-spondins supporting the Wnt pathway and Noggin, which inhibits differentiation cues from the bone morphogenetic protein (BMP) pathway, are crucial. Incorporating proteins with high activity and batch-to-batch consistency is key in creating a stable environment for organoids. At Bio-Techne, reagents are routinely tested side-by-side with both lots previously produced internally and competitor batches to ensure optimal bioactivity and purity and therefore superior organoid growth. Speaking from Bio-Techne, Anthony Person, Sr. Director of Protein Development, explained “we aim to deliver quality, highly bioactive, and consistent proteins every time”.

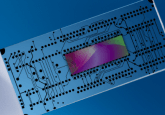

Robert Barrett, Cedars-Sinai Medical Center (CA, US), is routinely working with miniaturized organ-on-chip system models to study the pathogenesis of inflammatory bowel disease (IBD). Dr Barrett is committed to consistency: “We use a range of products from Bio-Techne. Induced pluripotent stem cells (iPSCs) were directed to form human intestinal organoids using noggin, EGF and CHIR99021 and these consistently generated high quality organoids.”

Researchers are also able to obtain reference documentation and protocols for generating the best environment for their organoids from Bio-Techne. As part of their dedicated Organoid Resource Database, lists of reagents used in research and development are available, as well as organoid recipes and protocols, thereby providing organoid researchers with all necessary reliable tools and enabling the next generation of scientific breakthroughs.

Summary

In summary, creating the best environment for organoids to grow and thrive requires the use of the best quality products such as growth factors, matrices and small molecules. Industry leaders Bio-Techne provide quality cell culture reagents [8], as well as resources and expert insights, to ensure produced organoids demonstrate optimal long-term growth and functionality. There are also custom services [9], ensuring that reagents match your organoid culture needs.

This feature has been brought to you in association with Bio-Techne. The opinions expressed in this feature are those of the author and do not necessarily reflect the views of RegMedNet or Future Science Group.

References

- Sanctuary C. New synthetic 3D culture systems to unlock the future of organoids in research and therapy. Med. 14(5), 555–557 (2017).

- Bio-Techne. Optimizing Organoid Culture Conditions: The Importance of Growth Factor Bioactivity and Reagent Consistency. Accessed 18/05/21

- Whygard T, Liu J, Darras FS, Waltzer WC, Romanov V. Organoid model of urothelial cancer: establishment and applications for bladder cancer research. BioTechniques. 69 (3), 193-199 (2020).

- Bio-Techne. Cultrex UltiMatrix Reduced Growth Factor Basement Membrane Extract. Accessed 24/05/21

- Bio-Techne. Cultrex Basement Membrane Extract (BME) and Extracellular Matrices (ECM). Accessed 24/05/21

- Heathman TRJ, Nienow AW, McCall MJ, Coopman K, Kara B, Hewitt CJ. The translation of cell-based therapies: clinical landscape and manufacturing challenges. Med. 10(1), 49–64 (2015).

- Bio-Techne. Building Organoids: Resources and Recipes for Organoids and other 3-D Cell Cultures. Accessed 24/05/21

- Bio-Techne. Recombinant Proteins Accessed 24/05/21

- Person A. Partner with Bio-Techne. Realize your protein & cell biology potential.